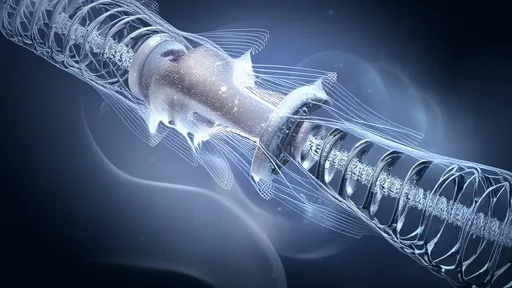

For decades, the quest to create artificial joints that mimic the seamless motion and durability of natural human joints has been a holy grail of biomedical engineering. Traditional prosthetic joints, though life-changing for millions, inevitably succumb to wear and tear over time. The friction between metal, ceramic, or polymer components generates microscopic debris, triggering inflammation and eventual implant failure. But now, a radical innovation inspired by nature’s own lubrication systems promises to rewrite the rules: magnetic fluid lubrication.

The concept draws from the extraordinary properties of synovial fluid, the natural lubricant in human joints. Synovial fluid isn’t just a passive viscous liquid—it’s a dynamic, shear-thinning substance that adapts to pressure and motion. Researchers have long sought to replicate this behavior synthetically, and magnetic fluids—colloidal suspensions of nanoscale ferromagnetic particles—offer a tantalizing solution. When subjected to magnetic fields, these fluids can change viscosity instantaneously, creating a near-frictionless interface between artificial joint surfaces.

How It Works: Harnessing Magnetic Fields for Adaptive Lubrication

At the heart of this breakthrough is the ability to control lubrication in real time. Unlike conventional lubricants, which degrade under mechanical stress, magnetic fluids respond to external magnetic fields by aligning their nanoparticles into chain-like structures. These chains create a cushioning effect that adjusts dynamically to load and motion. In an artificial knee or hip joint, embedded electromagnets could modulate the fluid’s viscosity during walking, running, or climbing stairs, effectively eliminating metal-on-metal contact.

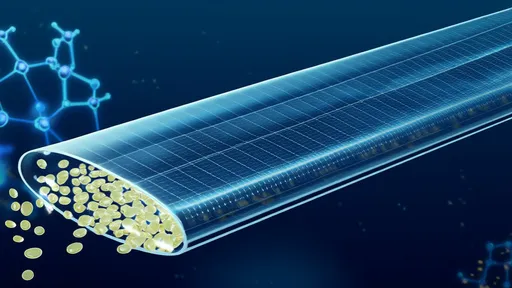

Early prototypes have demonstrated staggering results. In laboratory tests, joints lubricated with magnetic fluids showed wear rates reduced by over 99% compared to traditional designs. The fluid’s self-healing properties further enhance longevity; even if nanoparticles are lost over time, replenishment systems could theoretically maintain optimal lubrication indefinitely. This self-sustaining mechanism mirrors biological systems, where synovial fluid is continuously replenished by the joint capsule.

From Lab to Clinic: Overcoming Challenges

Despite its promise, translating magnetic fluid lubrication into clinical practice isn’t without hurdles. One major challenge is biocompatibility. The ferromagnetic nanoparticles must be coated with non-toxic materials to prevent immune reactions. Recent advances in biocompatible coatings, such as polyethylene glycol (PEG), have shown encouraging results in animal trials, with no signs of inflammation or toxicity.

Another obstacle is power supply. Electromagnets require energy, and implanting batteries or inductive charging systems adds complexity. Researchers are exploring passive magnetic systems using rare-earth magnets, which could generate sufficient fields without external power. Alternatively, piezoelectric materials might harvest energy from joint movement itself, creating a self-powered solution.

The Future: Beyond Joint Replacements

While artificial joints are the immediate focus, the implications of magnetic fluid lubrication extend far beyond orthopedics. Potential applications include high-performance bearings in aerospace, ultra-low-friction gears in automotive systems, and even minimally invasive surgical robots where precision movement is critical. The technology could also revolutionize prosthetics, enabling lightweight, noiseless limbs with lifelike articulation.

Industry leaders predict that the first magnetic fluid-lubricated artificial joints could enter human trials within five years. If successful, they may usher in an era where joint replacements last a lifetime, eliminating the need for risky revision surgeries. For millions suffering from arthritis or joint injuries, this bio-inspired innovation isn’t just an engineering feat—it’s a promise of pain-free mobility, forged at the intersection of biology and cutting-edge physics.

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025

By /Aug 14, 2025